With the development of biotechnology, freeze-drying technology has become more and more widely used in the field of biopharmaceuticals. In the past two decades, biopharmaceuticals have made breakthroughs in improving human immunity and genetic diseases. More and more The biological products are researched in the form of freeze-dried powder and applied in clinic.

【Biopharmaceutical freeze-drying application】

Biological products include proteins, antibodies, strains, cytokines, hormones, fermentation products and other microorganisms, cells and tissues, etc. After vacuum freeze-drying, the survival rate of proteins, live bacteria, live toxins and other microorganisms is above 80%, so biological products There are many freeze-drying applications.

Biopharmaceutical freeze-drying applications:

ØInjections: biological drugs (antibodies, vaccines, etc.), blood products, antibiotics, testing reagents, etc.;

Ø Raw materials: biological raw materials, probiotics, collagen and other cosmetic raw materials, Chinese herbal medicines, etc.;

【Biopharmaceutical Freeze-drying Process】

Biological products may be denatured during freeze-drying and storage. In order to deal with or reduce the denaturation of biological products during freeze-drying and long-term storage, two methods are usually adopted. The first way is to add protective agents to the formulation, and the second is to optimize the freeze-drying process.

1.Add protective agent

The lyoprotectant is an additive in the lyophilized preparation, which can reduce or prevent the denaturation effect of the lyophilization process on the protein. According to the difference in the stress imposed on the protein by the freeze-drying process and the drying process, the mechanism of action of protein protectants can be divided into cryoprotection mechanism and drying protection mechanism. There are many types of lyoprotectants, mainly including sugars, polyols, amino acids, polymers, surfactants, etc. In practice, one or more protectants are usually added according to the lyophilization characteristics of biological products.

2. Optimize the freeze-drying process

The freeze-drying requirement of biological products is to maintain the activity of the product, so the freeze-drying process is strictly required, and the control of pre-freezing temperature, rate, time, etc. is very important. By optimizing the freeze-drying process, the stability of biological products during the freeze-drying process and storage period can also be improved to a certain extent. The main steps that can be optimized in the freeze-drying process are pre-freezing, primary drying (sublimation drying), and secondary drying (analytic drying).

Pre-freezing process optimization - control the size of ice crystals. According to the denaturation mechanism of biological products, controlling the size of ice crystals during prefreezing is one of the main methods to improve the stability of biological products. Generally speaking, through quick freezing, that is, the method of pre-freezing the clapboard, the ice crystals will be smaller during the freeze-drying preparation process, the one-time drying (sublimation drying) time will be longer, and the surface area of the prepared freeze-dried powder will be larger. Therefore, during the pre-freezing process, the state of crystallization should be monitored at all times, and then the freeze-drying equipment should be controlled reasonably and flexibly to ensure that the crystallization is in a normal state.

One-time drying (sublimation drying) - change the drying temperature. Primary drying is the longest and most complicated step in the entire freeze-drying process. The ideal state of primary drying is to raise the temperature to the equilibrium temperature as soon as possible at a reasonable temperature, and shorten the equilibrium temperature time as much as possible to achieve a better drying effect. It can be seen from this stage that the freeze-drying temperature and vacuum degree control requirements high.

Secondary drying (analytical drying) - control the heating rate. Secondary drying is the last stage of freeze-drying, which mainly controls the temperature of biological products by raising the temperature of the partition. According to research, the slow temperature rise method is safer for product quality, and it is also applicable to biological products. Slow temperature rise has a great relationship with the performance and vacuum degree of the freeze dryer, and it should be controlled carefully.

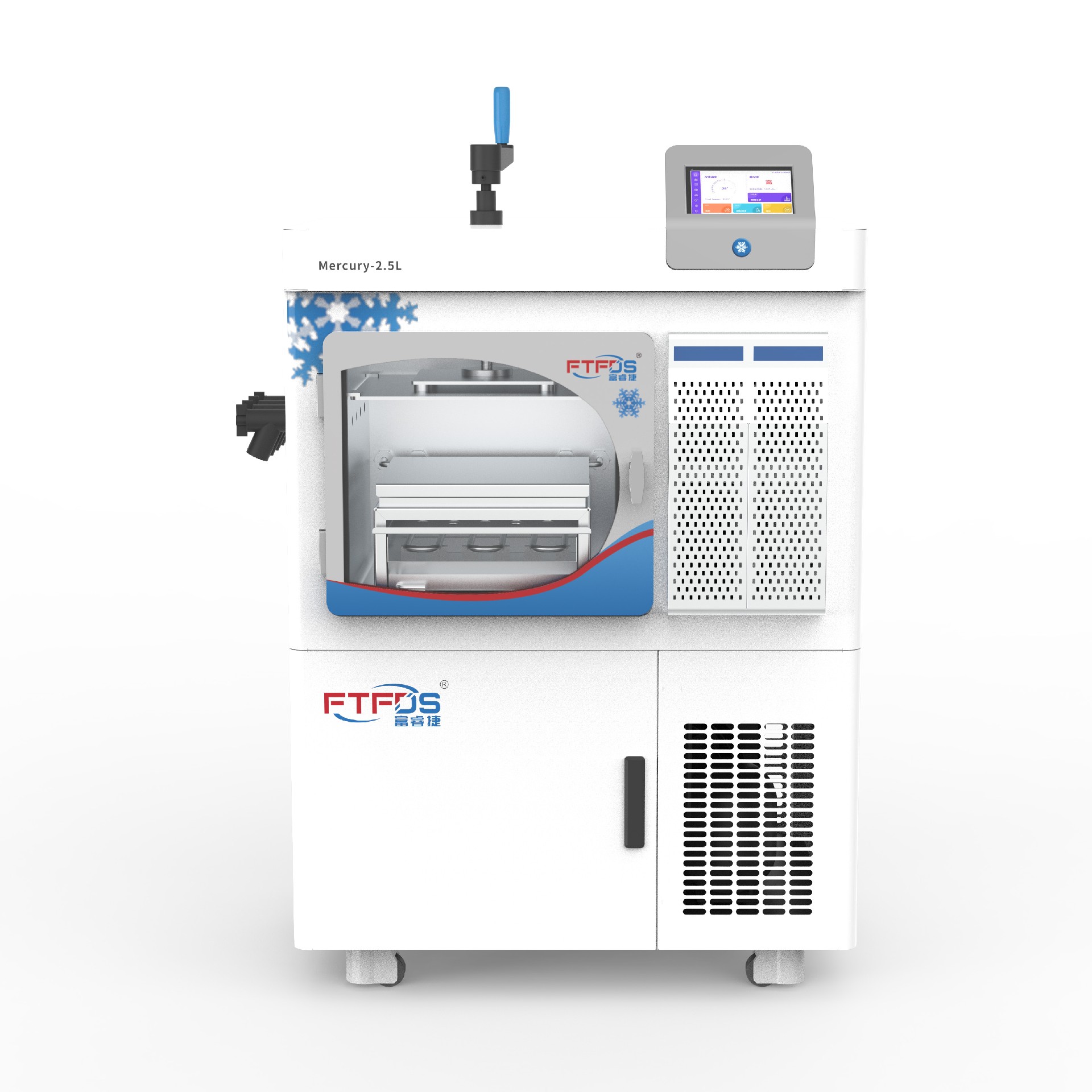

Biopharmaceutical freeze-drying application equipment-in-situ freeze-drying machine

Freeze-drying is a lengthy and harsh dehydration process. During the freeze-drying process of biological products, we pursue to optimize the freeze-drying curve, shorten the freeze-drying time, and maintain drug stability. These are not small challenges.

As a professional manufacturer of freeze-drying systems and solutions, Furuijie Technology has rich team experience in this area. For example, the Mercury series of in-situ freeze dryers can process standardized samples in medium/large scale, and can perform online capping of vials and eight-tube tubes. It is suitable for those who pursue freeze-drying technology, obtain freeze-drying curves, and shorten freeze-drying time Biopharmaceutical lyophilization applications.